Airtightness in preliminary stages of architecture design

From concept to handover, we describe what needs to happen at every RIBA stage for a successful airtightness test.

Introduction

Airtightness is not just something you do on test day. To pass the test takes much more than a big tube of silicone or expanding foam. It takes more than selecting tapes or membranes.

Airtightness, just like karate, means more than buying the right products. You can buy a white robe and a crash mat. But if you want to get the result, you are going to need to set your attitude, train and deliver.

It doesn’t have to be difficult, nor does it have to be expensive, but builders and designers do need to follow a process from the very earliest stages all the way through. Your process, and your attitude to quality, are more important than the specifications or products. You need to start thinking about airtightness early and follow it through the whole design and construction process; right up to the final test.

This article includes tips to help you pass the test first time, without resorting to last minute silicone repairs.

The RIBA stages

British Construction teams use the “RIBA Plan of Work” aka the RIBA stages to manage the design & build process.

- At the start you must define a clear scope and brief, and ensure you consider a very wide range of scenarios and strategies.

- As you continue, the plan clearly defines stages of detail for strategy, space and cost which help the client and design team refine the product in unison.

- The RIBA make clear requirements on the Construction stage and finally on Handover and “In-use” stages; to encourage thoughtful and successful delivery.

- Note the emphasis that the method puts on feedback of learning into new designs. We think that’s one of the most important activities.

In short, the RIBA Plan of Work is a common framework that allows diverse teams to work better together over the many years it takes to deliver a building. In this article, I am highlighting how I think airtightness fits into this.

RIBA Stage 0-2 Briefing & Concept design

The first three stages, from Stage 0 to Stage 2, is when you define the “rules of the game”. At this stage you define the scope and brief for the building you wish to deliver. You may include aspirations for performance in terms of quality, cost, comfort and sustainability. Bring a design team on board to develop the outline brief in to a clear scope. You should make sure to define the metrics for success, and how they will be measured. With your team you’ll highlight and manage key risks.

Agree what is an appropriate target for airtightness for the project:

- What is the bare minimum to pass building regulations? Here’s a link for what you have to do Airtightness in Building regulations in UK & ROI and why you might go further.

- What is easily achievable? What will cost more? Are there trigger points which unlock savings elsewhere?

- Meeting a defined target such as BREEAM or Passivhaus.

- Your building will be in use for 50 years and hopefully longer. Do you wish to future proof it now?

- You can’t go too tight! We debunk a few common myths about airtight buildings in this article. It’s a must, especially for flatulent clients.

The most important thing for you to do at this stage is to set the airtightness target in writing. You should include it in the project brief & ideally the design team appointments.

Tips for stages 0-2

- To reiterate: it is essential that you agree a suitable target and set it down in writing. Here’s some discussion on how to set an appropriate airtightness target.

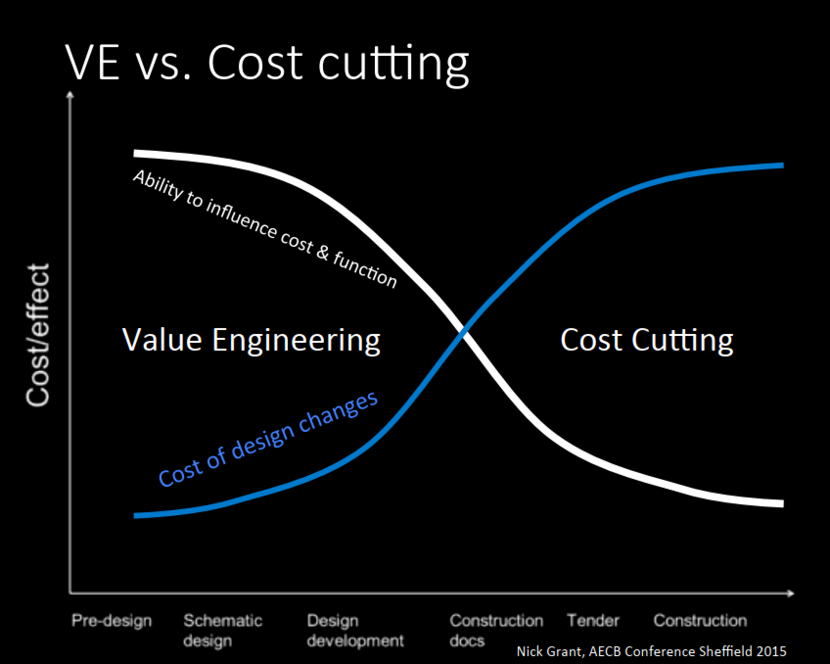

- This stage is your golden opportunity to rationalise the form and detail design, especially with regards to airtightness. It’s when actual Value Engineering (VE) gets done. VE later down the line is just cost cutting, as neatly illustrated below:

In the early stage you can make changes easily. Later on, it’s difficult and messy. This graph neatly illustrates that real Value Engineering doesn’t happen after Tender; it should happen in Stages 0-2 or 0-3.

- “The most expensive mistakes are made in the first five minutes” or, to put this another way: if you don’t review your early design from a buildability point of view, it will cost you later down the line!

- Reduce complexity in the form; every step in or step out introduces extra junctions in 2D and 3D which must be negotiated on site. A simple form for the AVCL envelope will go in quicker, perform better, and cost less – win all round.

- A complex building shape, with fiddly detailing, and ill-conceived curves make it even harder to do a good job; if you really need those flourishes, can you apply them externally to a simple AVCL.

- At this stage, you may start to set out what to use as the airtightness and vapour control layer (AVCL) in the roof, wall and floor; setting your intention now helps guide the detailing and build-ups.

- You should think about the need for a continuous airtight-line. This should be located on the warm side of the insulation, and outside of the structure. It should be as flat as is practical to be. Think simple, boxy forms.

- Seek advice from SIGA as early as possible – they are there to help, and its free!

SIGA Airtightness guide for RIBA stages

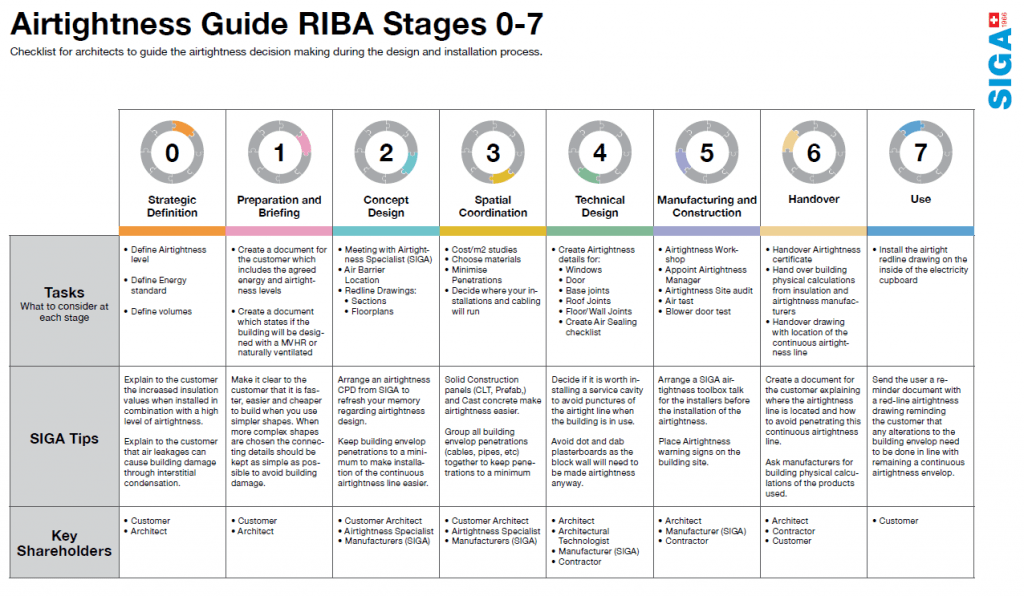

The SIGA team has created a handy guide to what to do at each stage, as Application Engineer Stan Admiraal explains:

“We have created a one page document for the use of the architect or designer, which they can print out and mount on their wall, to guide them through the design process. Often, we see architects to think about airtightness at a very late stage whilst SIGA could have helped them designing simpler airtight details and save them a lot of money in the long run. As Richard Cushing said “Think ahead! It wasn’t raining when Noah build the Ark.”

Download your copy of the RIBA Stages Guide here.

Conclusion

OK, so we’re on the way to becoming an airtightness ninja!

Be sure to use the early stages to define a challenging-yet-achievable airtightness target and set it down in writing.

Review your design thoroughly now, to make it buildable and affordable later.

Do you think we have we missed something critical? Let us know in the comments!

Links to helpful further resources

Passivhaus Trust Good Practice guide to airtightness

This is a detailed and wide-ranging report for architects, designers and builders, it is recommended bedside reading.

AECB page for airtightness guidance

This is in an accessible webpage format. It tuns you through the key aspects of airtightness, including webinar video recordings.

Passivhaus trust How to build a passivhaus

This guide covers a wider range of topics for high quality construction.

A practical guide to building airtight dwellings NHBC NF16

This is more contractor-focussed. Although it is a little out of date, and not especially aspirational, the basics are covered.

The Zero Carbon Hub Thermal Bridging Guide

Similarly to the NHBC document; this presents common building details in a clear graphical format. It includes helpful pointers on how to improve on-site quality.

Bertie Dixon

Bertie has practised building services engineering and sustainability consulting in the UK for 15 years. He is a certified PassivHaus planner. He is on a mission to help you deliver a high-quality building, one that does what it says on the tin.