Build airtight and save costs

The Ultimate Guide to Nearly Zero Energy Building

DOWNLOAD HERE

Do air leaks in the building fabric support healthy ventilation—or do they simply waste heat and compromise comfort? We take a closer look at the science behind this common assumption.

Picture: Sebastian Herrmann on Unsplash

Has your client ever said “I don’t want my building to be too airtight, how will I breathe?” Have they picked up an idea that airtight buildings are “unhealthy” because leaks are needed to let in fresh air?

There are a lot of myths about airtightness – as Bertie Dixon explained in his SIGA blog here.

But there are also myths about leakiness! The main myth is that leaks in the fabric provide a reliable, measurable contribution to the supply of fresh air.

I had a look into the science, and what I found out was:

Read on to learn more…

It is a commonly held belief – and one formally endorsed by many governments – that leaks in the building fabric provide useful ventilation. And alongside this belief there is a nervousness about airtight buildings: it is often suggested that you have to “balance” or “trade off” occupant health against energy saving, or that an airtight building is in some way unhealthy.

In the UK, the official energy model, the Standard Assessment Procedure (SAP) and the building regulations (Approved Document F) even use a calculation to estimate the amount of air they expect to enter the building via leaks.

The estimate is based on a “rule of thumb” that was first used in the United States in the 1980s. The rule states that the air change rate at normal pressure can be worked out by dividing the permeability (in ach at 50 Pa) by 20.

Thus in the UK, the authorities firstly assume that the UK permeability metric of m3/m2 @ 50 Pa is effectively the same as the leakage in ach @ 50Pa – which is roughly true, though it depends on the building form. Then they assume that if a building is leakier than 3m3/m2.h, 0.15 air changes per hour (ie 3/20) will be supplied by leakage.

This 0.15 ach is then subtracted from the ventilation rate required for any building fitted with ‘natural’ ventilation system (this means a system using intermittent extract fans in wet areas, and trickle inlets in living and bedrooms).

In the UK, these fabric leaks are considered an essential part of natural ventilation. This means you are required to build a leaky building – with a permeability of at least 3m3/m2 @50Pa – if you want to ventilate naturally. There are similar requirements in a number of European countries including Germany, Austria and the Netherlands.

Yet when air exchange in real-life leaky buildings is investigated, the one-in-20 rule appears less hard-and-fast. Several small studies have directly examined this. Even in the small number of buildings tested, air change rates ranged from almost double, down to less than half, of what the rule would have predicted. Air exchange rates were more often below than above predictions.

In one of the studies, by researchers in Nottingham, two houses with leakiness close to 4m3/m2.h had infiltration rates of 0.12 and 0.08 ach respectively. By contrast the rule of thumb would have predicted rates around 0.2ach for both.

Research suggests that ventilation rates of around 0.4 ach or above are “the minimum to to protect against health risks”. And the recommended air change rates in the UK ventilation regulations also work out at around (0.4 to 0.5ach) for a typical house.

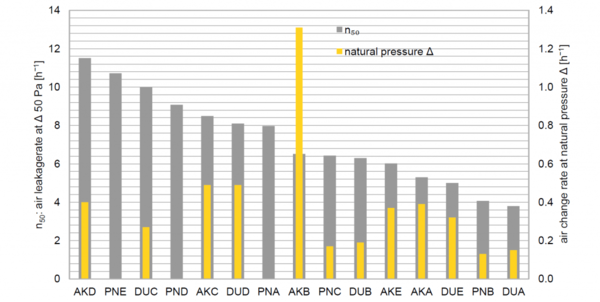

In her research at the University of Auckland in New Zealand, Kara Rosemeier also investigated fabric permeability and air exchange rates, this time in a sample of 15 houses in different parts of the country. Fabric leakiness ranged from below 4ach @50Pa, to higher than 11. However, rates of natural infiltration ranged from barely 0.1 ach to a remarkably draughty 1.2ach.

Strikingly, there appeared to be little or no relationship between the air change rates and permeability in the test dwellings (see chart). If the rule of thumb were reliable, the yellow bars (ach under normal conditions) would exactly half-fill the grey bars (test infiltration rate).

Kara Rosemeier – fabric permeability and air exchange rates Source: Kara Rosemeier

Air change rates at 50 Pa (grey bars) and average natural pressure differential (yellow bars). Dwellings arranged in descending order of fabric infiltration.

Thus, research shows that you cannot rely on the flow of air through leaky building fabric to make a reliable contribution to air exchange. In some cases, using the modelled estimates would lead to under-supply of fresh air; in others, there is a risk of over-ventilation and energy waste.

All of the natural air exchange measurements considered above were carried out with all internal doors open, and averaged for the whole dwelling.

However in real life, the accidental cracks and gaps on which ‘natural infiltration’ depends are unlikely to be evenly distributed around the house.

In one of these studies, differences of 30% in the air change rates were recorded between two different rooms in the same house. The researchers at Leeds Becket University used a smoke gun to find the air leakage paths. As expected, the room with higher air change rates (a bedroom) had more than its share of leakage paths, and the other rooms had fewer.

These differences may become particularly important when doors are closed – as, obviously, they often are. This was investigated by a team at UCL and the University of Loughborough. Jessica Few and colleagues compared whole house air change rates with rates in a single room with the door shut.

This test house was very leaky – the permeability was measured as 15m3/m2.h @50Pa. The air change rate for the whole house (with trickle vents closed but internal doors open) averaged at 0.7 ach (close to what would be predicted by the rule of thumb in fact). This is a level which the researchers considered to be over-ventilation. Opening the vents added a little to the air change rate, which rose to 0.8 ach.

The researchers then repeated the measurements, but in just one room, the living room, with the door closed.

With the trickle vent also closed, the air change rate in the living room was only 0.17 ach – less than one quarter of the whole house rate, and much too low for adequate ventilation. Opening the trickle vent increased the air change rate, but only to an average of 0.32 ach. This was still less than half of the whole house rate, and still not enough to supply the recommended 0.4 ach to occupants.

Why was the air so unevenly distributed? The team used smoke guns during the pressurisation test to trace the main air leakage paths. They found noticeable air leakage behind the kitchen cupboards – the location of the service entries, and under the stairs. These are both common air leakage paths in UK homes, and neither of them are located in living areas in most houses.

As the researchers concluded:

“Air is likely to be unevenly distributed around the building; higher air permeability does not necessarily mean that more ventilation is provided in the places it is needed.”

They add that although this house overall was very leaky, which would lead to discomfort and energy loss, “it cannot be assumed that the ventilation is adequate in rooms with the doors closed.”

Kara Rosemeier shares the concerns about relying on leakage to contribute reliably to the ventilation and indoor air quality. Adequate amounts of fresh air need to get to where people actually are “and leaks cannot guarantee this,” she says.

In the UK, the London Energy Transformation Initiative (LETI) , a coalition of over 1000 built environment organisations and individuals, has called on the UK government to remove the reliance on air leakage altogether. They warn that the route infiltration air takes into any building is unknown, and it may not reach all occupied rooms, risking “a significant reduction in indoor air quality, and increased health issues.”

These views are echoed by Anatolijs Borodinecs and colleagues at the Riga Technical University, who have studied air exchange in renovated apartments. They say that the job of the building envelope is to minimize the heat losses and the job of the ventilation system to provide air exchange. So the building envelope airtightness shouldn’t be dependent on type of ventilation systems.

What does this tell us about the idea that energy saving must be “balanced” against the requirement for fresh air? How leaky would we need to make our buildings, if we wanted to guarantee enough air exchange?

In the UK the government has responded to concerns about under-ventilation by proposing bigger ventilator sizes when the regulations are next updated. But as the relationship between holes in the fabric and air exchange is so uncertain, some homes would end up over-ventilated, energy-inefficient – and uncomfortable.

Is there ever a good “balance” that ensures occupants get good air quality, but at the same time, ensures they are comfortable, and their homes are energy efficient enough to meet our climate targets? Or do we have to live with the fact that to protect everyone’s health, some people will have to suffer perhaps double the infiltration heat loss than others, and more energy will be used as a result?

Perhaps there is no ‘sweet spot’ after all. This is certainly the position taken by LETI, which argues that to meet climate targets, permeability of dwellings should be limited to <3m3/m2.h, and all homes should have continuous mechanical ventilation sized to supply all fresh air needs, with none left to chance.

This echoes the Passivhaus approach, which uses very high airtightness and whole house heat recovery ventilation to ensure reliable indoor air quality along with very low levels of heat loss.

Simply mandating continuous mechanical ventilation in the building regulations would not guarantee good indoor air quality. Systems still have to be designed, installed, and commissioned correctly. In the UK at least, we don’t always get this right.

But Passivhaus has proved hundreds of times over that effective whole-house mechanical ventilation is possible, when client and contractor are united in their aims.

If designing and delivering effective mechanical ventilation is the only obstacle to improving fabric, and cutting carbon, isn’t it an obstacle we can tackle? Surely we have nothing to lose, and everything to gain, by building proper airtight homes, and ventilating them effectively.

With effective mechanical ventilation, there is no danger involved in maximising airtightness – only advantages, such as energy saving and comfort. And the air supply rate is known, and not merely guessed at.

Kate is a writer and researcher specialising in sustainable and healthy building and retrofit.

Added to my cart