Beware Thermal Bypass: How Air Affects Insulation's Job

Thermal bypass occurs when unwanted air movement undermines insulation. Architect Mark Siddall explains how airtightness, windtightness, and proper insulation prevent heat loss and moisture risks.

Kate de Selincourt talked to Mark Siddall and asked him to explain how thermal bypass may undermine building performance – and what we can do to prevent it.

Photo by Carol Hendersen from FreeImages

Back in the noughties, Architect Mark Siddall was one of the first people in mainstream construction – rather than in academia – to start thinking and talking about thermal bypass. And he’s still one of the most knowledgeable people out there. So when I decided I should get my head round the subject properly, he was the obvious person to ask.

Mark and I chatted about thermal bypass, and just some of the ways it can reduce energy performance – and how it sometimes brings other problems along with it.

I already knew that airtightness, and a snug insulation installation were important for thermal performance. But till we spoke, I didn’t appreciate how many ways cosiness could be undermined by stray air, moving around where it shouldn’t. I was also surprised by the many ways moving air could make moisture risks worse.

What is thermal bypass?

Mark explained what got him interested in the subject in the first place. “It was a bit more than 10 years ago, when we first began to hear a lot about the performance gap. Many of us were already committed to building buildings that used less energy. So it seemed pretty important to learn why this was going wrong.”

Party walls had a thermal bypass problem

“One of the important pieces of research at that time was a study carried out by Leeds Beckett (then Leeds Met) University,” Mark said. The team was investigating the energy performance of a housing development in Cheshire, northwest England, known as Stamford Brook. The homes were using a lot more energy than intended. It turned out that one of the main reasons was a problem they called ‘party wall thermal bypass’.

This finding caught Mark’s attention. “I was developing the design for the some terraced bungalows for older people, and was aiming for Passivhaus performance. I wondered, would we have this issue with the party walls? How would we avoid it?”

“I wanted to find out more, but there was really nothing said about thermal bypass in the industry (and largely, there still isn’t). So to investigate further, I started to look into academic research.

“It opened a wormhole into another world! I ended up reading 55 research papers, and writing a 16,000 word thesis!”

Researchers found bypass caused moisture problems

One paper that stood out to Mark was a study carried out in the US, at Princeton University, back in the late 1970’s. Researchers were investigating the escape of warm damp air into a cold roof space, causing heat loss – and moisture problems.

“The researchers discovered that warm air from heated basement rooms was finding its way up through spaces within the structure of the party walls. It was ending up in the roof, which was cold. This was not only causing heat loss, but carried a big moisture risk too.”

Open loop bypass is an open door for heat

The formal definition of this kind of thermal bypass is ‘open loop’ thermal bypass. This is when air passes through part of a structure, and carries heat away with it.

Cold air was getting into the cavities

Heat loss from the Stamford Brook houses was up to double what it should have been, because of this party wall problem. The researchers realised that for so much heat to be rising into the attic spaces, cold air must be getting into the cavity to feed the flow – the “open loop”.

As Mark put it: “The result was to that for all the good the party wall was doing them, the homes might as well have been detached!”

This particular thermal bypass problem has now been recognised in the building regulations, which require party wall cavities to be insulated.

Thermal bypass can carry moisture too

It’s not just party walls where this kind of heat loss happens. Whenever a building misses its airtightness target, you get unwanted heat loss. The exfiltration of warm air and infiltration of cold are forming an open loop.

Because warm air rises, warm moist indoor air can be particularly likely to find its way up into the roof. If the roof is cold, as the majority of UK pitched roofs are, there is then a risk of condensation.

“Think of a typical two storey house. It‘s 20 degrees inside, and 50% humidity, but zero degrees outdoors. Warm air is pushing upwards under the ceiling, because of the stack effect. In this situation the pressure is around 2 pascals – that’s equivalent of two bags of sugar per square metre of ceiling,” Mark says.

Tiny gaps allow warm air to escape

“The pressure means even tiny gaps and cracks in the ceiling will allow warm air to escape up into the roof space, and through the insulation.” Because of the temperature difference, moisture may then condense on the cold structures in the roof.

“Just a small crack 1mm wide and 1m long will allow an extra 360 g of water (i.e. a good glassful) into the roof space, every 24 hours.”

Guidance is missing

What bothers Mark is that although the stack effect is no secret, and moisture is a common cause of building failure, the building regulations don’t address this issue at all. No obvious target is given for ceiling airtightness – though this would be the way to stop this moisture escaping.

“Nothing anchors the requirements for airtightness in construction in terms of moisture,” Mark says. “The targets are only set in relation to energy. Yet air movement is also a moisture issue.”

Not all roofs can have vents

Unvented roofs are appropriate in some situations, he explains. “Sometimes there are local planning conditions, such as conservation areas and areas of outstanding natural beauty, that require roofs to look a certain way, leaving no room for vents. Research also suggests unvented roofs may be a good idea in places where fog, driven snow and rain or high winds are common.” But if the roof is not vented, but is only able to dry through the membrane, Mark is concerned the extra moisture might not be able to dry quickly enough. This could cause problems.

Moisture guidance for unvented roofs is frustratingly absent: it relates to vented roofs only. “There really isn’t any advice on how to avoid this risk,” Mark says. “We don’t really know how airtight ceilings need to be, and how best the roof should be constructed if it can’t have vents.

“There is also remarkably little research into it – which is why I’ve started doing some of my own!” Characteristically thorough, Mark has teamed up with a researcher at the University of Reading, Dr. Emmanuel Essah, to try to fill this gap in our knowledge.

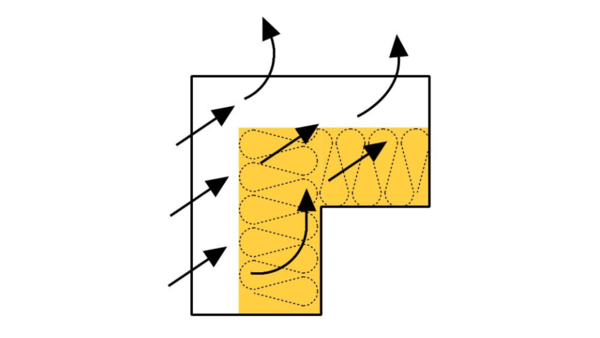

Cold air can steal heat from outside – without even coming in

Airtightness stops cold air getting into the living spaces. But even if the building is highly airtight, air movement can sneak heat away by other means. This is what had gone wrong at Stamford Brook – cold outside air was getting too close to the inside, even though it wasn’t coming in. The houses weren’t windtight.

Making a building windtight is like putting a cagoule over a woolly jumper on a windy day. It doesn’t add any more insulation, but it ensures the insulation in the jumper can work.

Mark told me about some research from Austria that had found dramatic examples of windtightness failure.

Corners are the coldest

Most structures are not this bad. However Canadian research found many buildings that had heat loss 40% higher than it should be, simply due to cold air getting into the insulation.

The most exposed parts of the building, unsurprisingly, are at highest risk: eaves, gables, ridges and corners.

These areas already suffer more heat loss and lower surface temperatures inside, because they are geometric thermal bridges. That is to say – they have a large outside surface, cooling a small area inside. Extra heat loss from the wind could make these spots even cooler, increasing the risk of localised condensation and mould growth.

This is another risk that Mark fears is being overlooked “There is no target or guidance for windtightness of a building’s outer skin.” By contrast, “in Norway they require a maximum permeability of 2.5 m3/m2 @ 50Pa. In a wall with a U-value of 0.25 W/m2K , this limits the heat loss from wind to an extra 5%.”

“In general, Passivhaus dwellings are aiming to build better insulating walls than that. But if the same absolute amount of heat is carried away by the wind, that would be a much higher percentage of the permitted loss.

“I did a rough calculation suggesting we might need a windtightness of more like 1 m3/m2 @ 50Pa to protect the insulation properly.”

Treat the outside like the inside

“Unfortunately, I don’t think there’s really any way actually to measure windtightness in construction,” says Mark. “But the Passivhaus buildings do meet their energy performance targets. This suggests the construction teams are getting the windtightness, as well as the airtightness, right.”

“I think people building to Passivhaus standards understand why attention to detail is important. If we look for the same attention to detail outside as we do inside, this can give the results we want.

“We need to treat the outside of the building – membrane, boards, render, or masonry, like the air barrier it is.”

Air-tightness and wind-tightness are both needed

Mark is keen to stress that airtightness inside and windtightness outside are generally both required. “I realise one response to this advice might be: if we effectively need a second air barrier outside, why not just make that the air-tight layer too?”

“It’s a reasonable question, but the issue is that we really don’t want warm moist air moving through the construction. If warm inside air meets cold elements near the outside, there is a very high probability of condensation.“

Keep it snug

If cold air gets behind the insulation, then clearly, heat will be removed. If the construction has a ventilated cavity, it is particularly important that the insulation is fitted snugly against the inner leaf, to guard against this.

In fact, it is always important in cavity construction that the insulation fits snugly against the inner leaf – even if the cavity itself is completely airtight inside and out.

This is because of a less obvious, but nonetheless, significant effect called closed loop thermal bypass.

Thermal bypass goes round in circles

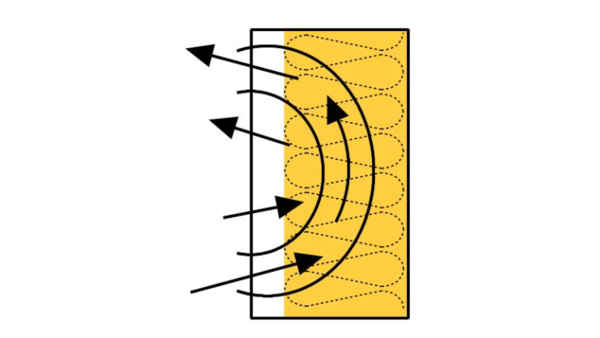

It’s pretty easy to understand that cold air whistling through insulation from outside would take away heat. But even if a cavity is perfectly sealed, air movement may steal heat from the inside and sneak it out, past the insulation. How does this happen?

It happens if air can move around within the cavity – in particular, if it can move from the inside to the outside. And unless the cavity is very carefully filled with tight-packed insulation, this is always a possibility.

Imagine a closed space that is warmer on one side than the other. Warmed air will rise on the warm side, and at the same time, the cooler air on the cooler side falls and passes across to replace the rising air. Thus, a rotating loop sets up. It is exactly this effect than enables a radiator to warm a whole room: the air it heats rises up the wall, passes along the ceiling and falls back, circulating around the room.

Sneaky conveyor belt steals heat

In a cavity, Mark explained, this loop is in effect a sneaky conveyor belt, steadily collecting warmth from the inside of the cavity and passing it to the cold outer masonry leaf, where it is lost, then going back to collect more. This process continues for as long as the unsuspecting occupants keep their heating on to power the process.

“The main purpose of insulation in a cavity is prevent conductive heat loss. But it also has an important role in blocking this heat conveyor,”

Mark explains.

“But to do this, it needs to be correctly installed. If the insulation isn’t snug against the masonry, air can move behind it and set up the ‘conveyor belt’ loop.”

No gaps please

Mark explains that with fibrous insulation, the best way to stop this is by fully filling the cavity. Loose insulation should be well packed, not loose and fluffy.

“The situation with rigid boards can be quite tricky, however,” he adds. “Rigid foam insulation is generally specified with a ventilated cavity – so wind protection is already reduced. If the bricklayers have left a few mortar snots in the cavity, rigid boards will not fit snugly against the inner leaf. This leaves a gap for air movement.”

“Ideally, you need a product that is sympathetic to realistic building practice,” Mark says. One solution researchers have suggested is to back rigid boards with a softer fibrous layer that can take up irregularities in the masonry.

It is also important that boards are closely butted up to each other without air gaps, for example around cavity ties. “Even narrow air gaps can result in significant heat loss. The lower the overall u-value, the more damage this kind of convection loop can do,” Mark warns.

“An increase in heat loss of about 160% greater than the calculated U-value is not uncommon, when air gaps exist behind the insulation.”

How not to do it! There is a substantial air gap between the insulation and the warm masonry in the cavity, meaning that cold air can move behind the insulation and remove heat to the outside, as air circulates within the cavity. Photo courtesy of https://www.kore-system.com/

Watch out for stray air!

After taking the trouble to design a building with wide cavities, thick insulation and all the best components in order to reduce heat loss, it certainly seems a shame to allow stray air to undermine a building’s performance. But, as I learned from Mark, that’s thermal bypass for you – very sneaky!

Hopefully knowing a bit more about the problem will make it easier to cut off the many ways air can move where we don’t want it to. My thanks to Mark for taking the time to share what he has learned.

If you want to know more about this subject, Mark has written several articles about it. Have a look here.

Mark Siddall is principal at LEAP, Low Energy Architectural Practice, based in Durham.

Mark has a 3-part documentary series that explores performance gaps, such as thermal bypass, and Passivhaus. You can watch the documentary at Passivhaus Secrets (PassivhausSecrets.co.uk)

Kate de Selincourt

Kate is a writer and researcher specialising in sustainable and healthy building and retrofit.