The Ultimate Guide to

A Safe Thermal Envelope

Download Guide

When it comes to vapour checks, there are some myths that are passed on from generation to generation. One myth is that there is an urgent need for a vapour barrier.

When it comes to vapour checks, there are some myths that are passed on from generation to generation. One myth is that there is an urgent need for a vapour barrier.

We often hear questions about vapour barriers. The building owner or the designer asks for a vapour barrier from our installing customers when finishing an attic. And with the question “Is the SIGA Majpell® 5 a vapour barrier?” the installer ends up asking us for technical advice. The question itself is quickly answered: ” No, Majpell® 5 is not a vapour barrier.” But was the question to ask for a vapour barrier originally correct at all? The explanation of different vapour Control layers, often takes more time.

PE film “in use”.

Usually, the term vapour barrier is used to describe a white or green PE film. Most of these membranes were installed as diffusion-inhibiting layers in roofs and walls over 30 years ago. However, we have seen pure polyethylene materials less and less on building sites for the past 10 years. Although the sheets are quite inexpensive to buy, some of the typical properties of these membranes no longer seem fit-for-purpose. On the one hand there are the processing properties: The membranes are quite stiff and cannot always be adhered to the substrate without problems. The decisive disadvantage from our point of view, however, is the high resistance to water vapour migration (vapour diffusion).

The sd-value is helpful for evaluating the different building materials in the roof. Materials with an sd-value greater than or equal to 100 m are considered to be vapour barriers. This is often also the stated sd value of PE films. In outdoor applications, on the other hand, sheets or sheet materials with very low sd values (less than 0.5 m) are usually used.

The decision for a vapour barrier is often made on the basis of a “rule of thumb”. It says that a roof or wall construction should be tigther on the inside than on the outside. Per se, there is nothing wrong with this principle. But the question that follows must be how vapour-tight it should be on the inside. Here too, a “rule of thumb” helps:

10 times more diffusion-proof than on the outside is optimal.

So let us assume that the sub-roofing membrane has an sd-value of less than 0.5. According to the rule of thumb, a membrane with an sd value of 5 metres on the inside then optimally fulfils the requirements of this rule. The expert will find these rules written down, for example, in the national standards for moisture protection of a building (BS5250:2011).

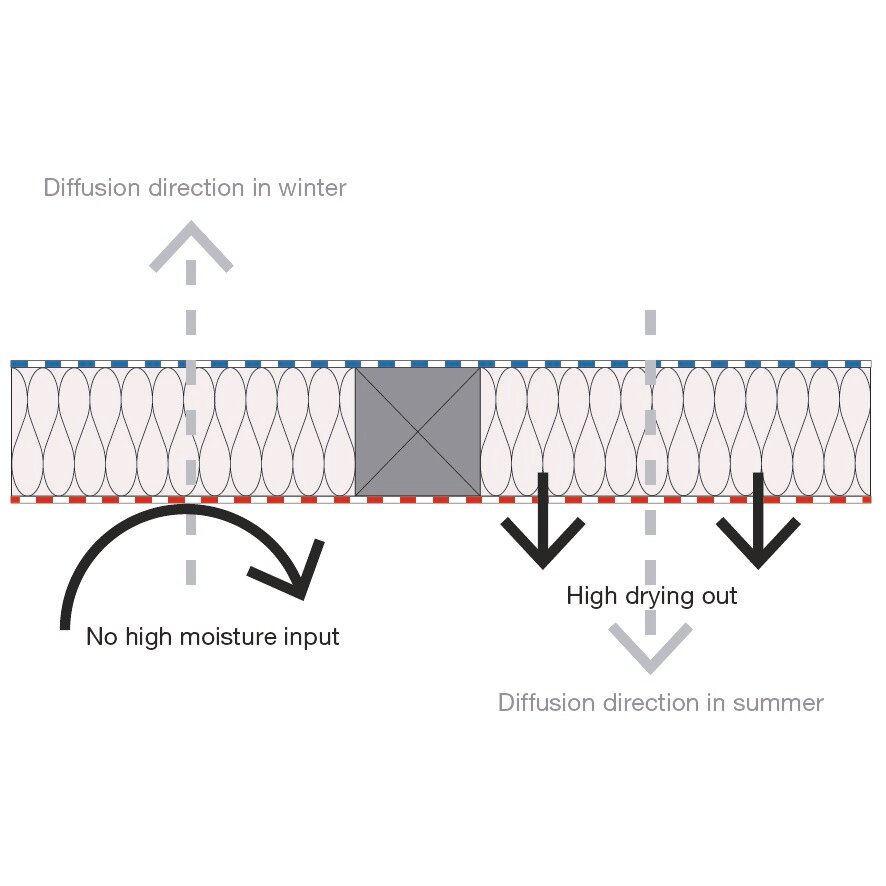

In Western Europe, Autumn and Winter are often typical for being wet, windy and cold, whilst spring and summer can often be sunny and warm. These distinctive seasonal changes can have a considerable influence on the moisture migration in a wall or roof construction. In Winter, moisture migrates from the room through the wall or roof to the outside. In Summer this process is reversed, and moisture migrates from the outside into the construction. Vapour barriers that prevent moisture from entering the construction in Winter however also prevent wall and roof constructions from drying out in Summer because of the high vapour diffusion resistance.

A building owner is quickly ready to decide on a vapour barrier. He or she wants the insulation to be permanently protected against moisture/condensation. Wet insulation keeps you just as warm as a wet jumper on a winters day (damp, ineffective insulation) and even structural damage, such as mould growth on wooden components. A frequent reason is poor installation of the vapour barrier. Poorly taped membrane overlaps or minor damages to the membrane allow moisture to flow into the wall-component by convection. The water vapour collects into the structure during the dew period (winter) and cannot dry out sufficiently inwards in summer due to the high diffusion resistance of the vapour barrier.

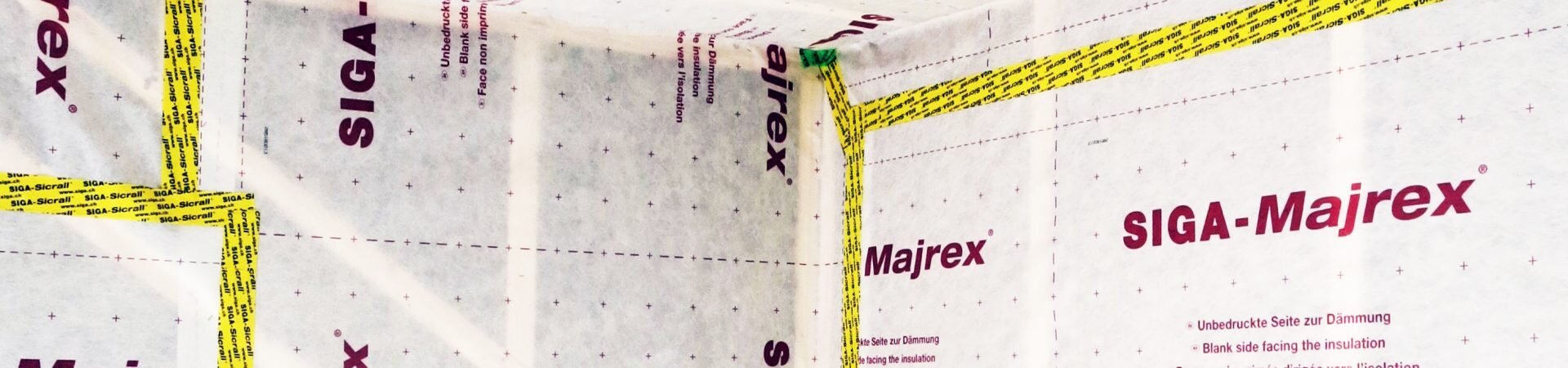

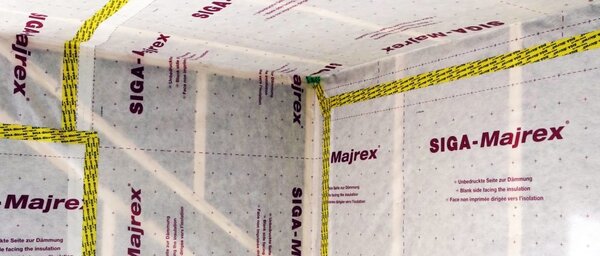

Vapour control layer SIGA Majrex® 200

But moisture damage can not only be caused by these faults. Even during the construction phase, building components can store large quantities of water. The brick wall was exposed to rain showers several times during the construction phase. Although the timber for the roof truss seems dry, it still contains sufficient quantities of water, which will dry out in the coming months and years. A vapour barrier with a moderate sd-value offers greater safety here, as the drying reserves are significantly higher.

Vapour diffusion can take place both in winter to the outside and in summer in addition to the inside; «the building can breathe».

For this reason, we recommend a vapour control layer in 99% of our customer requests, and not a vapour barrier.

Always remember this rule of thumb:

Plan and execute roof and wall inside as airtight as necessary and as vapour diffusion-open as possible.

This works well with the vapour control layer SIGA Majpell® 5. The directionally moisture-variable vapour control layer SIGA Majrex® offers our customers and their building owners even more safety.

This article was initially published on SIGA’s German blog. The author of this article is Jörg Wollnow, Application Engineer Central Europe at SIGA. He is a trained carpenter and qualified wood technician who has been working on the subject of airtightness for more than 20 years. He has already trained more than 30’000 professionals to become airtight champions.

HR Marketing and Employer Branding Manager on a mission to position SIGA as a great employer. Outside of work, she enjoys immersing herself in the world of books, passionately practices yoga, and is a proud mum.

Added to my cart