Top 6 rookie air sealing mistakes

Don’t get caught making these common rookie mistakes (and what to do instead!)

We’ve all been the Rookie at some point in our careers. Just like any rookie, we’re bound to make mistakes. But as building codes regionally continue to adopt stricter standards, those air sealing mistakes could create more headaches.

Here’s a few no-brainers to be on the lookout for. Getting rid of these rookie mistakes will help speed your transition to the air-sealing Big Leagues.

This is first on the list for a reason. Correct this mistake if you only pick one takeaway from this article.

Mistake 1 – Ignoring the foundation

As you know, 90% of the time your air barrier membrane shares the same plane as the sheathing (or actually is the sheathing itself).

Foam sill sealers, while good at keeping your mudsill isolated from green concrete, only stop drafts along the top of the foundation. How do foam sill sealers help seal an air barrier system, which is located at the sheathing?

Hint: They don’t! Fentrim® 430 grey does does…

Mistake 2 – Not sealing the top plate to… really anything

This one gets missed because no one thinks about it until they are staring at rows and rows of roof trusses that must somehow get detailed.

Our recommendation? Add air sealing to the menu earlier and pre-strip a membrane across the top plate during the framing.

There are a handful of ways to tackle sealing the top plate, just make sure you talk with your roofer to identify venting strategies in relation to air barrier layers. (Your air seal might even be on the interior — Majrex® is a great option.)

The same situation applies to unconditioned roofs or soffets that break up the wall plane. Make sure the air-barrier doesn’t get interrupted by pre-stripping a membrane or adding extra sheathing or blocking.

Mistake 3 – Letting “someone else” take care of it

The air barrier layer is unique because it comes in direct contact with nearly every tradesperson on a project. As a result, it takes a group effort to achieve a good end result and avoid an air sealing mistake (like forgetting to seal wire penetrations).

So, if you see the air barrier damaged or faulty, do something about it!

- Tell your superintendent or tape it up with Wigluv® on the spot

- If you are the one running the project, communicate the importance of catching air sealing mistakes to all your subs

- Assign someone to be a dedicated “air barrier specialist”

Mistake 4 – Assuming every sealant / tape / membrane is like every other sealant / tape / membrane that you’ve ever used

Read the labels.

Some tapes need primers to stick well. Others take a couple days to cure, or require a certain pressure for the molecules to align. Some sealants can be used in your baby’s nursery. Others can corrode metal.

A lot of science goes into adhesives and coatings, and there are many products now we couldn’t even have imagined of 15 years ago. Make sure all the products you use play well together. And though it might be tempting to use that roll of duct tape in a pinch, remember that it too was invented for a specific purpose.

(And it wasn’t air sealing!)

Mistake 5 – Red lining in your mind

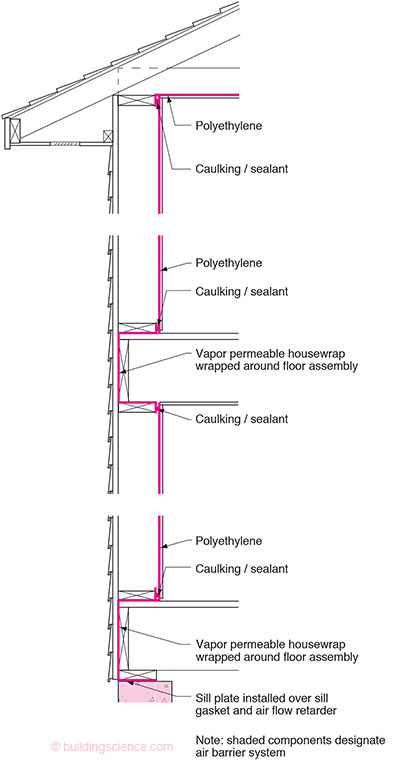

The concept of “red lining” means adding an overlay on the elevation drawings to trace the path of air barrier continuity.

Usually this is done in red to correspond to warmth (the net result of good air sealing). It’s a practice that high performance builders use but not something an architect will commonly generate for you.

Take the time to sketch out the new air barrier path. Don’t assume you can visualize all the elements. And for kicks, it never hurts to “blue line” it too (drainage path for water).

Mistake 6 – Leaving a mess

Air sealing is all about prep. Piles of sawdust or drywall powder, errant pulled nails, dirt and mud from the site — they will end up contaminating your tape / sealant / primer. Clean messes as you go to prevent debris from creating adhesion problems.

Conclusion

Were you making any of these rookie air sealing mistakes?

There’s no time like the present to up your building game by building airtight and preventing heat and cool air from escaping. Sign up for our FREE monthly email newsletter for the latest practical tips about building air and weathertight.

Give it a try.

Jessica Kumor

Jessica is SIGA North America's Marketing Director. It's her job to deliver you the latest research and practical tips for building air and weathertight buildings. When she's not interviewing customers and posting about building science you can find her refinishing furniture.