Futurebuild 2020: Key Trends in Sustainable Construction

At Futurebuild 2020, the UK’s largest sustainable construction fair, we explored trends shaping the industry, with a focus on self-organised action in response to government inaction on climate change.

Self-Organisation

Despite rising popular concern over climate change, the UK government remain stubbornly unmoved. Longstanding despair in the industry has recently been replaced with self-organised action; if the authorities aren’t going to act, we can show them how.

The Passivhaus Trust Passivhaus Superstars presentation was one of the best attended events of the day. Perhaps this is part of the ‘bounce’ from the recent Stirling Prize win, at Gold Smith street.

ACAN Architects Climate Action Network hosted a confessional booth for professionals to share their ecological sins in confidence. Brutalist concrete eco-homes, anyone?

The folk at LETI have recently launched their Climate emergency design guide, which is better researched, far more relevant, and far more clearly presented than anything we expect from the recent disappointing “Future Homes consultation” (aka fiddling while Rome burns; its implementation in 2025 is expected to cause no ripples).

“LETI have grasped the urgency and scale of the problem and have defined what needs to be done right now.”

LETI hosted a number of talks, their members and excerpts of the design guide were in evidence in numerous presentations.

Automated design

Entire hectares of Futurebuild are given over to digital design. Bryden Wood’s offering stood out. They claim to be able to go from site selection to a fully designed, coordinated and costed housing scheme (circa RIBA stage 4) in as little as 15 minutes.

“That is six to twelve months work, done in 15 minutes. It’s faster than building in Minecraft!”

It starts with PRISM, a free open source web app, available to anyone. Firstly, you select your site from a data-rich 3D model of London (more cities are yet to be added). This sets out massing and apartment layouts. It returns feedback on KPIs such as GIA/NIA efficiency, and suitability for construction by ‘modern methods of construction’ e.g offsite manufacture.

This links through to two further (closed, paid) stages to stage 4 coordinated architecture, structure and MEP.

Coordinated Architecture, Structure and MEP in 15 minutes

The automation doesn’t stop there. Bryden Wood have developed a toolkit of construction components that can be easily assembled on site. Current example of this with Landsec in Southwark .

This isn’t a replacement for experienced design teams, it is a powerful tool to ensure their decisions are properly informed.

The implications are potentially profound – this means that you can test your early stage design for impacts on cost & space efficiency at the time it needs to be done- in stage 1 or 2 . So, you may achieve genuine value engineering . Nick Grant will be pleased!

No-regrets Retrofit

If the UK is at all serious about reaching zero carbon by 2050, the retrofit of existing buildings is a challenge that dwarfs new build . However, it is messier, can be riskier and the budget is usually far less.

“So, despite its reputation as a Cinderella of UK construction, it encouraged us to see that Retrofit had a healthy showing at Futurebuild.”

The Green Register are a small not for profit training scheme. Their aim is to offer low carbon training to self-selecting builders. A lot of the syllabus is based on the clear advice published by the zero-carbon hub .

The Green Register model is to ‘train the trainers’, such that an ever- increasing pool of efficiency-literate builders might pull the industry up by its bootstraps (or ratchet straps, perhaps).

Energiesprong is a mass-retrofit programme that engages closely with councils, contractors and, especially residents to deliver fully funded deep retrofit.

“It is possibly our best hope for transforming millions of low & medium rise homes. “

At Future build, the winners of an Energiesprong UK design competition exhibited practical solutions for three categories:

- Build-up-add two extra floors to four-story blocks, alongside efficiency measures.

- Net zero for low rise- detailed and costed proposals to improve housing of fewer than four stories.

- Billing, metering and monitoring solutions- how to measure homes to ensure best health and efficiency for least cost.

The proposals are a blueprint for the UK’s near future.

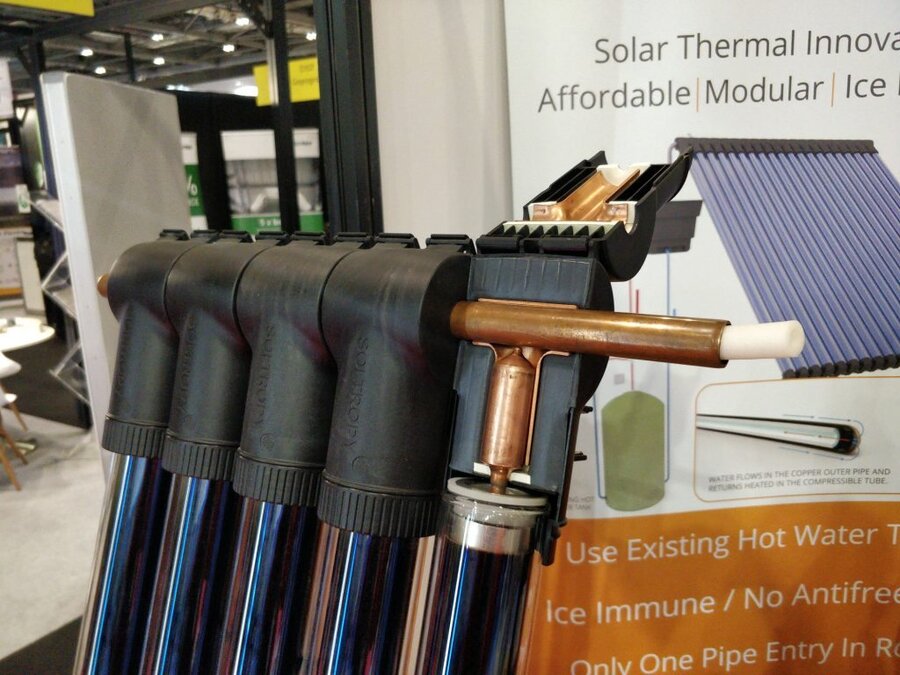

Simple Solar thermal

Soltropy is a solar thermal collector system that claims to combine the efficiency of evacuated tube with the robustness of flat plate. It is the first evacuated tube collector we’ve seen that doesn’t require antifreeze, that is its USP.

Soltropy solar thermal. Modular connections, and a concentric, deformable return pipe arrangement – that’s the clever bit.

This means it could be almost a ‘fit and forget’ system, which can happily freeze in winter and boil in summer, with no damage caused. They offer a 20-year warranty, which shows they are walking the talk. Be aware that you must be connect the panel to an open-vented heating system. It is not yet MCS registered.

The tubes themselves are standard components: which keeps the purchase and repair costs down.

All this simplification makes solar thermal a candidate for meaningful heat contribution in the winter, meaning it could become a suitable technology for zero carbon buildings. Provided, of course, that you have the space. Watch this roof.

An as-built test for actual heat loss

We know we can test a building for airtightness towards the end of construction. An airtightness test is a powerful way for clients to verify building quality and performance. But there’s no such test for heat loss from building fabric. You can run a ‘co-heating test’, but it takes many days, which is disruptive and expensive.

Veritherm claim to be able to do a co-heating test overnight. The test takes place just after the airtightness test. With a ~10% accuracy, this promises to be a non-invasive rapid and affordable method to test heat loss through fabric.

If coupled with a thermographic survey it can highlight any improvements required. Just like air testing, you could run this test part-way through construction, to catch issues before it’s too late.

Airtightness testing has fundamentally improved building practice. Now could be the time for the thermal envelope to shape up.

“This will be disruptive for both designers and contractors.”

New (at least new to us) thermal break products

We’re always on the hunt for new products to reduce heat loss from tricky details. If we can do it more efficiently, more simply, and with a local product then all the better.

Armatherm manufactures lightweight & high strength composites for thermal break applications. Therefore, they are competitors to products from Shoeck, Ancon, Foam glass, Compacfoam, Farrat etc.

Light gauge steel walls or walls with weather screens usually use thin profile steel or aluminium to support the outer layer. This metal is crossing the insulation layer. As we know from a previous article this can cause significant thermal bridging and moisture issues.

Armatherm’s ‘ZGIRT’ is a thin gauge profile of thermoset resin has the potential to transform thermal performance and longevity of these systems. The limiting factor is likely to be fire resistance (as is so often the case with new Approved Document B), so you should check its compliance for the situation. Still, this product deserves a high profile.

Plug the performance gap with Gapotape

As Mark Siddal has done well to highlight over the years, thermal bypass of warm air around poorly fitting insulation is a major cause of the performance gap, moisture damage , and discomfort. This problem is most acute with rigid insulation.

Gapotape is a wide self-adhesive foam tape that does what it says on the tin; it fills the gap between rigid insulation and roof rafters/other adjacent timbers. So, you can get the enhanced U-value of rigid insulation, without the poor-quality install that you sometimes see. It’s simple but brilliant.

Wind-tight membrane for open facades

SIGA’s showcased their latest product Majvest® 700 SOB. This is an external airtight and weatherproof layer designed for the modern issues we face in high-rise construction.

Facades often exposed to the elements for several months. With the skills-gap this could run up to a year because of availability of skill full bricklayers and façade installers. Majvest® 700 SOB is excellent for building sites with a longer UV-exposure.

Fire safety regulations are changing. SIGA offers a membrane which is one of the best performers in the market in fire tests. Tested free hanging as a classB-s1,d0 membrane; Majvest® 700 SOB isn’t sealed to the substrate to reach it’s fire classification.

“Majvest® 700 SOB complies with the building regulation for high-rise buildings above 18 meters.”

And it looks good, too. Open clad weather-screens, leave the membrane not only visible but also exposed to daily UV. Not every membrane is upto this task. Majvest® 700 SOB is UV stable, and completely branding free, so no annoying writing will be visible when you look closely.

Not even the taping will be visible. Because there is no taping. SIGA pre-apply the edges with self-bonding strips.

This is a membrane for minimalists (safe, efficient & comfortable minimalists).

Note: The descriptions here of non-SIGA products are wholly editorial & wholly non-commercial.

Do you want to start building airtight? Book a CPD now!

Bertie Dixon

Bertie has practised building services engineering and sustainability consulting in the UK for 15 years. He is a certified PassivHaus planner. He is on a mission to help you deliver a high-quality building, one that does what it says on the tin.