Do you need to know what a perm rating is?

You’re gonna want to know this next time you’re evaluating building materials for your wall assembly.

Do you need to know what a perm rating is?

Short answer?

Yes.

But there’s more to it than that.

(Isn’t that always the case?)

So today we’re talking perm rating.

What is a Perm Rating?

A perm rating is the unit telling us the mass rate of water vapor flowing through one square foot of material.

In the U.S., a perm is defined as 1 grain of water vapor per hour, per square foot, per inch of mercury.

A metric perm is defined as 1 gram of water vapor per day, per square meter, per millimeter of mercury.

In both cases, the higher the perm rating, the more water vapor can travel through a material.

What is Vapor Permeability?

If you paid attention in science class, you’ll remember that water can take different forms:

- Solid (Ice)

- Liquid (Drinking water)

- Gas (Steam)

Vapor permeability describes how much water in its gas form can pass through a material.

You’re typically going to find vapor permeability descriptions with perm ratings on building materials like house wraps and vapor barriers.

Vapor Permeability Classifications

There are four commonly accepted classifications to describe vapor permeability of construction materials:

- Vapor impermeable: 0.1 perms or less

- Example: Sheet metal flashing and 6-mil polypropylene

- Vapor semi-impermeable: 1.0 perms or less and greater than 0.1 perm

- Example: Asphalt-coated kraft paper

- Vapor semi-permeable: 10 perms or less and greater than 1.0 perm

- Example: Plywood

- Vapor permeable: greater than 10 perms

- Example: Most common house wraps

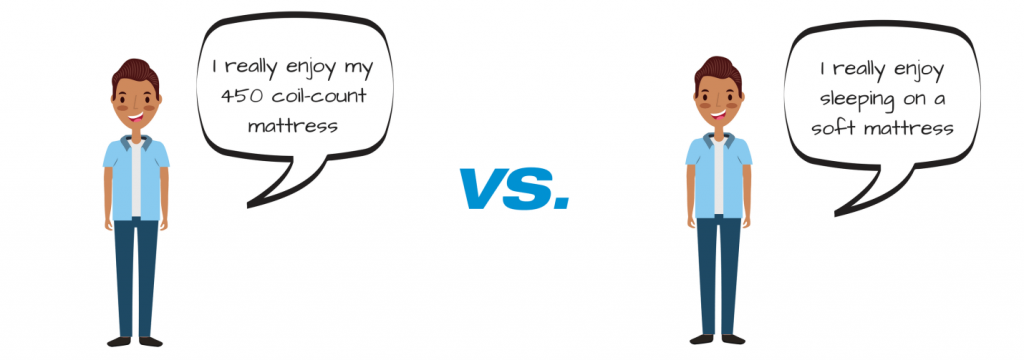

You can think of these classifications just like you would mattress firmness descriptions.

A “hard” mattress may mean it has 1,000-1,500 coils, while a “soft” mattress may mean it has 300-500 coils.

We could go around saying the exact coil count when we describe our beds, but it’s easier to describe products by using classifications that have defined limits.

Coil count numbers are completely made up and not based on fact. We’re not mattress experts.

Why Do Perm Ratings Matter?

Because wall cavities get wet. Daily life and little acts of mayhem like a roof leaking can lead to potential water damage.

Situations that create moisture in your wall assembly can include:

- Roof leaks

- Plumbing leaks

- Wet weather during construction

- Condensation

- Showering

- Cooking

- People breathing

- A dog

All of that can create a lot of water buildup in your wall assembly.

Walls get wet and require a way to dry out. When a wall can’t dry out, it becomes vulnerable to damage like mold and rot.

What’s a Good Perm Rating?

Unfortunately, there is no universal “good” perm rating.

Things like climate zone and your building envelope design are going to impact how permeable your house wrap should be.

Water vapor is always trying to balance itself out. In general, that means:

- If you’re building in a northern climate, water vapor will travel from the inside out.

- If you’re building in a southern climate, water vapor will travel from the outside in.

- If you’re living in the middle of the U.S., vapor could travel in either direction based on what time of year it is.

What Products Report a Perm Rating?

You’re going to find most conversations around perm rating and vapor permeability when discussing the building envelope of your building and the materials it’s made of, including house wraps, flashing, air barriers, vapor barriers, etc., depending on the job.

Read Joseph Lstiburek’s Building Science Corporation piece titled “Understanding Vapor Barriers” to get a stronger understanding of vapor barriers.

Conclusion

With a firmer understanding of what a perm rating is and the information it’s reporting to you, you’ll be better able to design, build and engineer a building envelope built to last.

Just remember that every new element in your building assembly, as well as your local climate, impacts what materials are best for the job.

Jessica Kumor

Jessica is SIGA North America's Marketing Director. It's her job to deliver you the latest research and practical tips for building air and weathertight buildings. When she's not interviewing customers and posting about building science you can find her refinishing furniture.